Fuel injectors are among the most critical components of modern internal combustion engines. They are tasked with delivering precise amounts of fuel into the engine’s combustion chamber to ensure efficient operation. When functioning correctly, fuel injectors help maintain smooth engine performance, optimise fuel economy, and reduce emissions. However, when they malfunction, the repercussions can be severe, leading to damage across various engine systems.

The Role of Fuel Injectors

Modern vehicles rely on fuel injectors to achieve precise fuel delivery. Unlike older carburettor systems, fuel injectors spray a finely atomised mist of fuel directly into the engine’s combustion chamber. This ensures efficient mixing with air, which is critical for combustion. Any deviation from this finely-tuned process can disrupt engine performance and potentially cause damage to other components.

Diesel fuel injectors, in particular, operate at extremely high pressures—often exceeding 30,000 PSI—to ensure effective atomisation and combustion. When the spray pattern from these injectors is compromised, it can lead to significant engine damage.

Common Issues with Faulty Fuel Injectors

When a fuel injector malfunctions, it can result in various issues:

Leaking Fuel Injectors – A leaking injector can cause excess fuel to drip into the combustion chamber, creating a rich fuel mixture (too much fuel and not enough air). This can lead to problems such as:

- Carbon buildup on pistons and valves.

- Reduced engine efficiency and power.

- Increased emissions may cause the vehicle to fail regulatory standards.

Clogged Fuel Injectors

A clogged injector delivers insufficient fuel, resulting in a lean mixture (not enough fuel). This can cause:

- Engine overheating.

- Potential damage to pistons and cylinder walls due to excessive heat.

- Engine knocking can be catastrophic over time.

Electrical Failures

- If the electronic components of a fuel injector fail, the injector may stop delivering fuel altogether, leading to misfires, rough idling, or even complete engine stalling.

High-Pressure Spray Pattern Failures

Diesel fuel injectors operating at high pressures can develop distorted spray patterns due to erosion, clogging, or contamination. This can result in:

- Uneven fuel distribution leads to inefficient combustion.

- Hot spots in the combustion chamber can cause overheating and damage to pistons.

- Increased emissions due to incomplete combustion.

- Engine knocking caused by improper fuel-air mixing.

Catastrophic Piston Damage

A faulty diesel fuel injector can cause severe engine damage, including putting a hole in a piston. This typically happens in cases where the injector:

- Over-fuels the combustion chamber, injecting excessive fuel and creating abnormally high pressure and temperatures that can damage the piston, sometimes to the point of forming a hole.

- Leaks or dribbles fuel even when the engine is not running, leading to pooling inside the combustion chamber. This can cause conditions like hydro-locking or improper ignition, resulting in severe detonation and localised overheating of the piston, potentially melting or eroding it.

- Produces an incorrect fuel spray pattern, leading to uneven combustion, hot spots, or excessive pressure on one side of the piston, which can cause mechanical failure over time.

How Faulty Injectors Cause Secondary Damage

A malfunctioning fuel injector doesn’t just affect fuel delivery; it can also have a domino effect, damaging other critical components of the engine:

Catalytic Converter Damage

Unburnt fuel from a leaking injector can pass into the exhaust system. The catalytic converter is designed to reduce harmful emissions but is not built to handle raw fuel. This can lead to overheating, clogging, or even permanent damage to the catalytic converter.

- A customer complains of a rotten egg smell (indicative of sulphur) and reduced performance. Upon inspection, the catalytic converter is clogged due to excessive unburnt fuel.

Fuel Pump Overload

A clogged fuel injector forces the fuel pump to work harder to maintain the required fuel pressure. Over time, this strain can lead to premature fuel pump failure.

- A vehicle’s fuel pump fails prematurely. Diagnostics reveal a clogged injector, which caused the pump to overcompensate.

Increased Carbon Deposits

Incomplete combustion caused by malfunctioning injectors can lead to carbon deposits forming on critical engine components such as valves, cylinder walls, and the combustion chamber.

- A vehicle exhibits poor acceleration and reduced fuel efficiency. Inspection uncovers heavy carbon buildup due to incomplete combustion caused by faulty injectors.

Engine Misfires and Damage

When injectors fail to deliver the correct amount of fuel, it can lead to engine misfires. Misfires not only reduce engine performance but can also result in damage to the cylinder head and spark plugs.

- A customer reports rough idling and difficulty starting the engine. Testing reveals misfires caused by uneven fuel delivery from faulty injectors.

Erosion from Contaminated Fuel

Contaminants like water or dirt can erode high-pressure diesel injector nozzles, altering the spray pattern and compromising combustion.

- Example: Water contamination in diesel fuel causes injector tip erosion, leading to uneven spray patterns and increased emissions. Regular use of water-separating fuel filters can prevent such issues.

CARBON REMOVAL GALLERY

Australian Car Models Prone to Injector Failures

Certain Australian car models have been reported to experience fuel injector issues more frequently than others. Notable examples include:

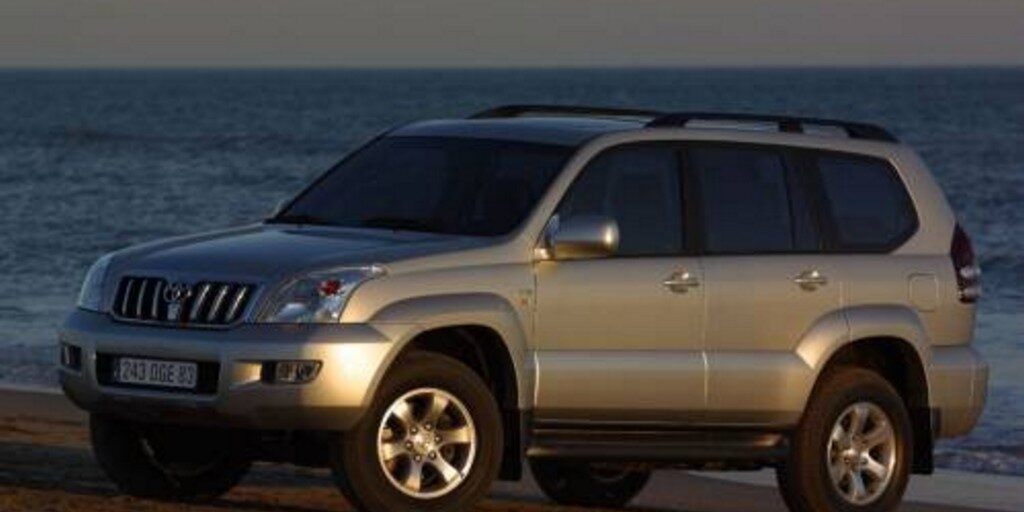

Toyota Hilux and Prado (2005-2007 models)

- These vehicles are known for injector failures, primarily due to dirty fuel clogging the injectors. Common symptoms include the “death rattle” noise and difficulty starting, particularly in cold weather. Toyota addressed this issue in later models by introducing improved fuel filters. Regular maintenance, including changing filters every 10,000 to 20,000 kilometres, can mitigate these problems.

Mercedes-Benz Vehicles with OM651 Engines (circa 2008)

- Some Mercedes-Benz models experienced injector failures due to defective piezo injectors, which were later replaced with more reliable solenoid injectors. Common issues included vehicles entering limp mode or complete engine stalling after 50,000 kilometres.

Volkswagen Models with 1.5/1.6 TDi Engines

- These engines have been reported to suffer from injector failures, often linked to fuel adulteration. Using high-quality fuel and adhering to maintenance schedules are critical to avoid such problems.

Prevention and Maintenance

To prevent damage caused by faulty fuel injectors, regular maintenance is essential. Here are some tips:

- Use Quality Fuel: Poor-quality fuel can lead to injector clogs. Opt for reputable brands and consider using fuel additives to keep injectors clean.

- Periodic Cleaning: Professional injector cleaning services can remove carbon deposits and improve fuel spray patterns.

- Routine Inspection: During regular vehicle servicing, ask your mechanic to inspect the fuel injectors for leaks, clogs, or electrical issues.

- Respond to Warning Signs: Pay attention to symptoms like reduced performance, rough idling, or unusual smells. Early diagnosis can prevent more extensive damage.

A Little Maintenance Goes A Long Way

Fuel injectors are small yet vital components that play a significant role in engine performance. Their failure can trigger a cascade of issues, from reduced efficiency to significant engine damage. By understanding the potential risks and maintaining your vehicle proactively, you can avoid costly repairs and ensure your engine runs smoothly for years to come.

If you suspect your vehicle has fuel injector issues or want professional assistance, Intake Cleaning offers comprehensive injector cleaning and replacement services to restore your engine’s performance.

Is your car’s performance not up to standard? Book a

Is your car’s performance not up to standard? Book a