Modern engines, especially those with direct injection (DI) systems, are more susceptible to carbon buildup compared to older engines that use port fuel injection (PFI). The primary reason for this is the design of the fuel delivery system and how modern engines handle combustion. Carbon buildup in DI engines often forms on the intake valves, and if left unchecked, it can significantly affect performance, fuel efficiency, and engine longevity. Let’s break down the reasons for this buildup and how shell blasting (or walnut shell blasting) is used to clean it.

Modern engines, especially those with direct injection (DI) systems, are more susceptible to carbon buildup compared to older engines that use port fuel injection (PFI). The primary reason for this is the design of the fuel delivery system and how modern engines handle combustion. Carbon buildup in DI engines often forms on the intake valves, and if left unchecked, it can significantly affect performance, fuel efficiency, and engine longevity. Let’s break down the reasons for this buildup and how shell blasting (or walnut shell blasting) is used to clean it.

Why Do Modern Engines Suffer from Carbon Buildup?

- Direct Injection (DI) Technology

In a port fuel injection (PFI) system, fuel is injected directly into the intake manifold before the intake valves, which allows the fuel to clean the intake valves as it passes through. However, in direct injection (DI) engines, fuel is injected directly into the combustion chamber, bypassing the intake valves entirely. This means that no fuel touches the intake valves to wash away carbon deposits, which can accumulate over time.

High-Pressure Fuel Injection

DI engines operate with higher fuel pressures to atomize fuel more finely for better combustion. While this improves fuel efficiency and power, it also creates more opportunities for carbon deposits to form in the combustion chamber. These deposits are typically from incomplete combustion, particularly when the engine is running at partial load or during short trips, where combustion isn’t always optimal.

Combustion Conditions

When an engine is running under certain conditions—like idling or during light load driving—combustion can be less than perfect. Incomplete combustion can leave behind unburned hydrocarbons, which mix with soot and form carbon deposits. This carbon can then stick to intake valves, pistons, and injectors. These deposits contribute to poor combustion and worsen the engine’s performance over time.

PCV and EGR Systems

Modern engines use Positive Crankcase Ventilation (PCV) and Exhaust Gas Recirculation (EGR) systems to reduce emissions and improve efficiency. However, these systems can also contribute to carbon buildup. For example:

- PCV systems can introduce oil vapours into the intake system, which burn and leave carbon deposits on the intake valves and pistons.

- EGR systems recirculate exhaust gases back into the intake manifold to reduce nitrogen oxide (NOx) emissions. However, these exhaust gases contain carbon and other particulates that can build up on the intake valves over time.

Short Trips and Low Operating Temperatures

Engines that are primarily used for short trips or are driven in city traffic may not reach their optimal operating temperature. When engines don’t run at the proper temperature for extended periods, combustion is less efficient, leading to carbon formation. This is especially problematic for DI engines because there’s no “valve washing” action from the fuel to clean the intake valves.

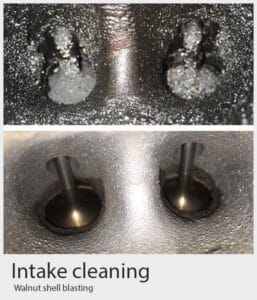

How Does Shell Blasting (Walnut Shell Blasting) Fix Carbon Buildup?

Shell blasting, commonly referred to as walnut shell blasting, is a cleaning process that uses finely ground walnut shells (or similar abrasive materials) to remove carbon deposits from the intake valves, combustion chambers, and other engine components. This method is effective, non-damaging, and safe for the engine.

Here’s how shell blasting works and why it is an ideal solution to carbon buildup:

Non-Abrasive and Safe for Engine Parts

Unlike harsh metal abrasives or sandblasting, walnut shells are soft enough to clean carbon deposits without damaging sensitive engine parts. The walnut shells are crushed into small pieces and used in a controlled, pressurized environment to remove carbon buildup from areas like intake valves, combustion chambers, and intake ports.

- Safe for valves and ports: The walnut shell material is gentle enough not to scratch or damage the intake valves, cylinder head, or ports, making it an ideal choice for cleaning these delicate areas.

Effective Carbon Removal

Walnut shell blasting is highly effective at removing stubborn carbon deposits. The shells are finely ground, and when they are blasted at the carbon buildup, they act like an abrasive, gently scrubbing away the accumulated carbon without causing any damage to the engine’s internal components.

- Precision cleaning: The abrasive material can be directed at specific areas where carbon has built up, such as the intake valves or intake manifold, breaking down the hard carbon deposits and preventing them from causing performance issues.

Improved Airflow and Combustion

Carbon buildup on the intake valves reduces the flow of air and fuel into the combustion chamber. This can lead to poor engine performance, misfires, and reduced fuel efficiency. When carbon is removed through shell blasting:

- Restored airflow: Cleaning the intake valves restores their ability to allow the correct volume of air into the combustion chamber, optimizing the engine’s ability to produce power efficiently.

- Better combustion: Clean intake valves help ensure that the air-fuel mixture enters the chamber properly, improving the efficiency of the combustion process, reducing emissions, and enhancing engine performance.

Prevent Engine Knock and Misfires

Excessive carbon buildup can create hot spots in the combustion chamber, which can lead to pre-ignition or knocking. These hot spots can cause uneven combustion, which, over time, can damage the engine. By removing the carbon deposits, walnut shell blasting helps:

- Prevent knocking: With cleaner intake valves and combustion chambers, the chances of hot spots causing pre-ignition are minimised.

- Improve ignition consistency: The engine will experience more consistent combustion, reducing the likelihood of misfires.

Restores Engine Power and Throttle Response

As carbon builds up on the intake valves, it can reduce engine power, cause rough idling, and make acceleration feel sluggish. By cleaning the carbon buildup with walnut shell blasting:

- Restored throttle response: The engine will regain its ability to respond quickly to throttle input, improving acceleration and performance.

- Increased power: With reduced carbon deposits, the engine will run more efficiently, translating into more power and smoother operation.

Long-Term Engine Health

By regularly cleaning the intake system with walnut shell blasting, you can help prevent long-term damage caused by carbon buildup. Carbon deposits that are left unchecked can cause serious issues like valve damage, poor compression, and increased emissions.

- Prevents further damage: Removing carbon buildup reduces the risk of damage to the intake valves, combustion chamber, and other engine components.

- Prolong engine lifespan: Regular maintenance, including walnut shell blasting, can help keep your engine running smoothly for a longer period of time.

Conclusion: Benefits of Walnut Shell Blasting for Modern Engines

Walnut shell blasting offers a safe, effective, and non-invasive method for removing carbon buildup in direct injection engines. This cleaning process addresses the root cause of carbon accumulation—especially on intake valves—and restores engine performance, efficiency, and longevity. By:

- Removing carbon buildup,

- Restoring airflow and combustion efficiency,

- Preventing knocking and misfires,

- Improving throttle response and fuel economy,

walnut shell blasting helps ensure that your engine operates at peak performance, reduces the risk of major repairs, and prolongs the overall lifespan of your vehicle. It’s a great preventive measure for modern engines that are more prone to carbon buildup due to their design and operating conditions.